| Green Spring Farm's Apple Fermentation Tank |

|

by Debbie Robison July 25, 2006 |

|

|

| SYNOPSIS |

Across the lane from Green Spring Farm’s springhouse is a ruin that likely originally operated as a fermentation tank for Fountain Beattie’s apple cider, applejack, and apple brandy manufacturing. Beattie grew apples in orchards on both sides of Little River Turnpike and along the hillside leading to the springhouse and fermentation tank. Fountain Beattie was formerly a Civil War lieutenant who rode as a guerilla-style raider with his friend, Captain John Singleton Mosby. After the war, Beattie was a government revenue officer who raided moonshiners, though he possessed his own government licensed still for distilling spirits. John Mosby Beattie, Fountain Beattie’s son, noted that they had a large concrete tank for apple cider, jack, and apple brandy. The fermentation tank appears to be in new condition in a c.1900 photo; the whitewash is bright and clean. When the Straights purchased the farm, the tank was a ruin, where all that remained were walls and painted beams that Michael Straight later learned was a brandy press. |

| SPACE FUNCTION |

|

The Cider Makers’ Hand Book, A Complete Guide for Making and Keeping Pure Cider written by J. M. Trowbridge in 1890 was researched to provide information on contemporary cider making practices. Trowbridge felt that the best apples for making cider were the Russet and Crab apples, though they were not the best table fruits. Apples mature through three periods: the growing, the ripening, and the sweating stages. The first two stages occur while the fruit is still on the tree, while the last stage occurs after the fruit is gathered. The sweating stage occurs when the starch in the apple is converted to sugar and is further beneficial because the volume of water in the apple is reduced due to evaporation. Apples were harvested by shaking the apple tree so that the apples dropped onto a harvesting blanket that was raised off the ground with stakes. It was best, if there was no threat of frost, to leave the apples in small piles out in the open exposed to the air, wind, and sunshine rather than placed in large heaps or in closed sheds, barns, or bins where they would be subject to mustiness. The apples should have been raised from the ground on a floor of boards, cornstalks, or straw; and could have been protected from a light frost by covering them with straw or old newspapers. After the apples had sweated, tests were performed to determine the correct mix of apple varieties to optimize the sugar:acid ratio. A saccharometer measured the proportion of dissolved saccharine (sugar) in a syrup.

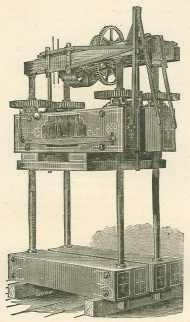

There were various types of mills used for extracting the juice from apples and reducing the fruit to pulp. The larger manufacturers may have used steam-powered mills, while the family farm used a hand-operated mill. Alternatively, as was the case at Green Spring Farm, a press was used to extract the juice from the pulp. From the Cider Maker's Handbook, 1890 Contemporary procedures indicate that apple juice was expressed into

large vats, or tanks, … where it is allowed to remain until the commencement of

fermentation has thrown a tenacious, frothy scum to the surface. This is

carefully skimmed off and removed as long as it continues to rise… Michael Straight commented in an interview that there was a brandy

press at the ruin. When

we got there the whole slope behind the house was dotted with very old and

unproductive apple trees. And when we went down to the house by the river –

which was not a house but just walls – we found within these walls we found

very heavy and beautifully painted beams…It turned out to be a brandy press. It is supposed that Beattie pressed the apple juice directly into the

chambers of the fermentation tank. Fermentation involves a chemical reaction

resulting in the release of carbonic acid gas. Thus the tanks could not be

sealed and must, at a minimum, have allowed the release of the gas. The partial below-grade location of the concrete tank provided the

advantage of more constant and lower temperatures that would have resulted in a

cider with less alcohol but more bouquet

and flavor.

In an oral interview, John Mosby Beattie

recollected a large concrete tank for

apple cider, jack and brandy. Perhaps each of the four chambers was used to

manufacture the different alcoholic beverages. Following completion of fermentation, a process that converts saccharine

to alcohol, the procedure must be halted or the result would be vinegar.

Fermentation during the Beattie period was halted by Pasteurization, a method

of heating the cider. Apple jack was historically made by freezing apple wine (higher alcohol

content than hard cider) and removing the water that freezes on the top, thus

leaving a higher alcohol content beverage. Each day, less ice forms on the

surface, until eventually no additional ice forms at that temperature. This process

may have been accomplished in the fermentation tank during a cold weather

season. Apple brandy is made by distilling fermented apple juice (cider). Beattie is known to have had a government licensed still. |

| DESCRIPTION OF EXISTING CONDITIONS |

|

The fermenation tank, now in ruin, measures 13’-6” square. The perimeter walls are approximately 10 ½” thick and are made up of varying sized cobblestones set in a mortar bed. The corners of the walls were formed with brick beginning about 1’-0” above grade. The structure is nestled into the hill, 1’-0” above grade at the south façade and 5’-4 ½” above grade at the north façade. The top of the foundation wall, which was originally level, has crumbled in several areas. The walls have a ½” finish coat of a concrete parging at the interior and exterior surfaces. Some whitewash remains on the parge. The structure is divided into 4 equal chambers separated by walls of the same construction and width as the perimeter walls. Archaeological investigations determined that the floor of the northeast chamber was constructed of cobblestone covered with a cement parge. |

| PRINCIPAL PHASES OF CONSTRUCTION |

|

The fermentation tank appears to be relatively new in a c. 1900 photo. The top of the walls of the tank were level and were whitewashed on the interior and exterior. Cleanliness was necessary for the production of quality cider.

Courtesy Fairfax County Park Authority |

| KEY INDICATORS |

|

Oral history interviews note that the Beattie’s had a large concrete tank for apple cider, jack, and brandy. The 1890 book The Cider Makers’ Hand Book described the fermentation process occurring in tanks. The structure at one time contained an apple press. In an oral interview, Michael Straight said that he was referring to the springhouse; however, the springhouse, in which he lived when he first arrived, had already been rehabilitated into a cottage and was not a ruin of only walls. The expanded and rehabilitated cottage appears in a 1937 aerial photo and on the 1942 Farrand landscape plans.

Archaeological investigations determined that the tank had an impervious floor. |